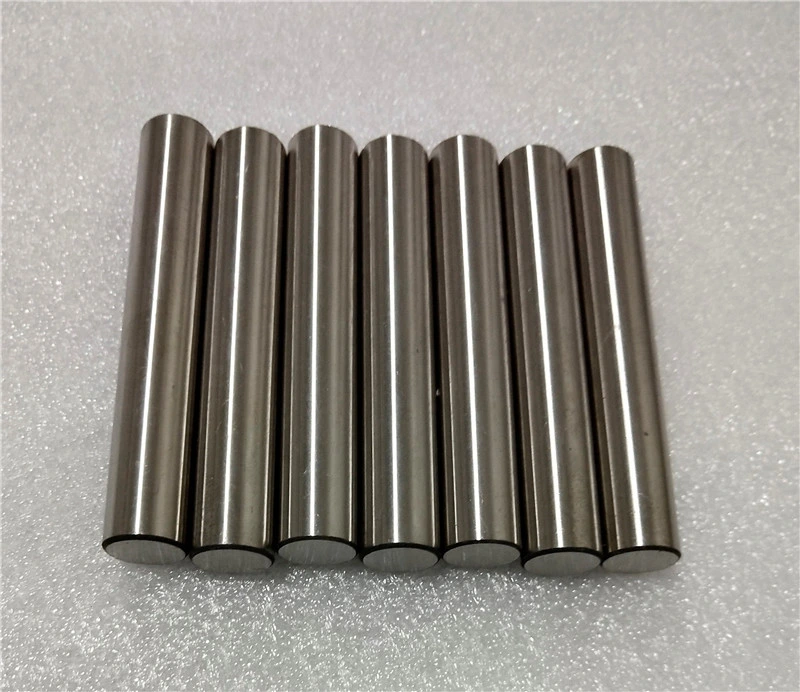

Aluminum Nickel Cobalt Permanent Cylinder Sintered AlNiCo Magnets Cast AlNiCo Magnet

1. Production Name:AlNiCo Magnet A. Sintered & Cast AlNiCo Though it names AlNiCo, it is not an alloy containing Aluminu;

Basic Info

| Model NO. | Cast AlNiCo Magnet or Sintered AlNiCo Magnet |

| Application | Electronic Products, Speaker Magnet, Industrial Magnet, Motor Magnet, AlNiCo Magnet |

| Shape | Round |

| Coating | Depend on Customer′s Request |

| Grade | Depend on Customer′s Request According to Grade |

| Size | Depend on Customer′s Request |

| Material | Sintered AlNiCo Magnet or Cast AlNiCo Magnet |

| Specifications | Depend on Customer′s Request |

| Lead Time | 30-35days |

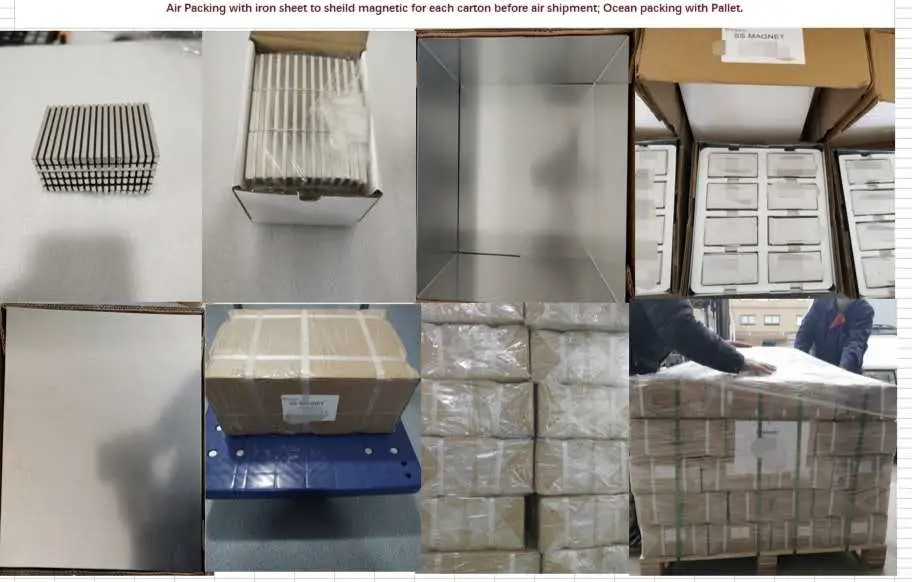

| Shipping Method | Air Shipment or Ocean Shipment |

| Certification | RoHS Reach MSDS |

| Usage | High Working Temperature |

| Type of Company | Direct Factory |

| Quality Assurance | Yes |

| Port of Departure | Ningbo Shanghai Guangzhou |

| MOQ | Depend on Customer′s Request |

| Tolerance | Standard or Depend on Customer′s Request |

| Payment Method | T/T Paypal Western Union |

| Plating | No or Nickel or Plating,etc |

| Service After Service | Yes |

| Transport Package | Air Packing or Ocean Packing |

| Specification | Depend on customer′s reqeust |

| Trademark | SS Magnet |

| Origin | China |

| HS Code | 8505111000 |

| Production Capacity | 3000 Tons Per Year |

Product Description

1. Production Name:AlNiCo Magnet

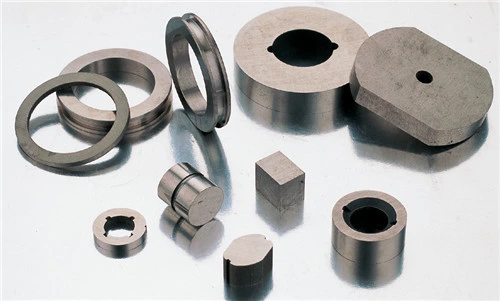

A. Sintered & Cast AlNiCo

Though it names AlNiCo, it is not an alloy containing Aluminum (Al), Nickel (Ni), Cobalt (Co). It also contains Cobalt, Nickel, and Aluminum with the addition of Iron, Copper, and sometimes Titanium that help make them become stronger permanent magnets. Max Working Temperature of AlNiCo ranges from 450°C to 550°C. There are two kinds of AlNiCo, Sintered AlNiCo and Cast AlNiCo. Cast magnets may be manufactured in complex shapes and the mould charge (sand mould) is cheap. But due to the sand mould edges, cast alnico has darkened edges with a slightly rough texture. To get smooth surface, grounding is needed. Sintered AlNiCo offer slightly lower magnetic properties but better mechanical characteristics. Most AlNiCo magnet grades are anisotropic (they can only be magnetized in a single axis /direction - they are the more powerful magnet grades of AlNiCo. The others are isotropic (they can be magnetized in any direction or directions) - they are weaker but offer more design and performance flexibility.

*Customized designs are available.

*Max working temperature can be as high as 550°C.

*Disadvantage: Br and BH (max) are not as high as rare earth magnet.

*Advantage: High energies and relatively low coercivity; High magnetic flux density; low mould charge; stable temperature properties; easy to shape.

B.Application:

Electronic Ignition Systems

Watt Hour Meters

Medical Instruments

Guitar Pickups

Industrial Motors

Hand Tools

Vending Machines

Automatic Control Appliance

| Magnetic and Physical Properties of Cast Alnico Magnet | |||||||||||||

| Grades | Equivalent MMPA | Remanence | Coercive Force | Maximum Energy Product | Density | Reversible Temp. Coefficient | Reversible Temp. Coefficient | Curie T emp. | Temp. Coefficient | Remark | |||

| Class | Br | Hcb | (BH)max | g/cm3 | α(Br) | α(Hcj) | TC | TW | |||||

| mT | Gs | KA/m | Oe | KJ/m3 | MGOe | %/ºC | %/ºC | ºC | ºC | ||||

| LN10 | ALNICO 3 | 600 | 6000 | 40 | 500 | 10 | 1.2 | 6.9 | -0.03 | -0.02 | 810 | 450 | Isotropy |

| LNG13 | ALNICO 2 | 700 | 7000 | 48 | 600 | 12.8 | 1.6 | 7.2 | -0.03 | 0.02 | 810 | 450 | |

| LNGT18 | ALNICO 8 | 580 | 5800 | 100 | 1250 | 18 | 2.2 | 7.3 | -0.025 | 0.02 | 860 | 550 | |

| LNG37 | ALNICO 5 | 1200 | 12000 | 48 | 600 | 37 | 4.65 | 7.3 | -0.02 | 0.02 | 850 | 525 | Anisotropy |

| LNG40 | 1250 | 12500 | 48 | 600 | 40 | 5 | 7.3 | ||||||

| LNG44 | 1250 | 12500 | 52 | 650 | 44 | 5.5 | 7.3 | ||||||

| LNG52 | ALNICO 5DG | 1300 | 13000 | 56 | 700 | 52 | 6.5 | 7.3 | |||||

| LNG60 | ALNICO5-7 | 1350 | 13500 | 59 | 740 | 60 | 7.5 | 7.3 | |||||

| LNGT28 | ALNICO 6 | 1000 | 10000 | 57.6 | 720 | 28 | 3.5 | 7.3 | -0.02 | 0.03 | 850 | 525 | |

| LNGT36J | ALNICO 8HC | 700 | 7000 | 140 | 1750 | 36 | 4.5 | 7.3 | -0.025 | 0.02 | 860 | 550 | |

| LNGT38 | ALNICO 8 | 800 | 8000 | 110 | 1380 | 38 | 4.75 | 7.3 | -0.025 | 0.02 | 860 | 550 | |

| LNGT40 | 820 | 8200 | 110 | 1380 | 40 | 5 | 7.3 | -0.025 | 860 | 550 | |||

| LNGT60 | ALNICO 9 | 900 | 9000 | 110 | 1380 | 60 | 7.5 | 7.3 | -0.025 | 0.02 | 860 | 550 | |

| LNGT72 | 1050 | 10500 | 112 | 1400 | 72 | 9 | 7.3 | -0.025 | 860 | 550 | |||

| Sintered AlNiCo Typical Magnetic Properties | |||||||||||

| Grade | Remanence | Coercivity | Intrinsic Coercivity | Max. Energy Product | Density | Working | Remark | ||||

| Temp | |||||||||||

| Br | Hcb | Hcj | (BH)max | Tc | |||||||

| KGs | T | KOe | Ka/m | KOe | Ka/m | MGOe | Kj/m3 | g/cm3 | ºC | ||

| FLN8 | 5.2 | 0.52 | 0.5 | 40 | 0.54 | 43 | 1.0-1.25 | 8-10 | 6.8 | 760 | Isotropic |

| FLNG12 | 7 | 0.7 | 0.5 | 40 | 0.54 | 43 | 1.5-1.75 | 12-14 | 7 | 810 | |

| FLNGT14 | 5.7 | 0.57 | 0.95 | 76 | 0.98 | 78 | 1.75-2.0 | 14-16 | 7.1 | 850 | |

| FLNGT18 | 5.6 | 0.56 | 1.1 | 88 | 1.13 | 90 | 2.25-2.75 | 18-22 | 7.2 | 850 | |

| FLNG28 | 10.5 | 1.05 | 0.58 | 46 | 0.59 | 47 | 3.5-4.15 | 28-33 | 7.2 | 850 | Anisotropic |

| FLNG34 | 11 | 1.1 | 0.63 | 50 | 0.64 | 51 | 4.3-4.8 | 34-38 | 7.2 | 890 | |

| FLNGT28 | 10 | 1 | 0.7 | 56 | 0.71 | 57 | 3.5-3.8 | 28-30 | 7.2 | 850 | |

| FKNGT31 | 7.8 | 0.78 | 1.3 | 104 | 1.13 | 90 | 3.9-4.5 | 31-36 | 7.2 | 890 | |

| FLNG33J | 6.5 | 0.65 | 1.7 | 135 | 1.88 | 150 | 4.15-4.5 | 33-36 | 7.2 | 850 | |

| FLNGT38 | 8 | 0.8 | 1.55 | 123 | 1.58 | 126 | 4.75-5.3 | 38-42 | 7.2 | 850 | |

| FLNGT42 | 8.8 | 0.88 | 1.5 | 120 | 1.53 | 122 | 5.3-6.0 | 42-48 | 7.25 | 850 | |

2.Quality Control

We can provide you all customized magnetd, magnetic applications and design them for you too!

Solutions for cost saving for you to choose the most suitable magnetic products.

Welcome to your enquiry anytime and we will reply you within 24hours in time.

Contact Person:Cary Li

You may also like

Send inquiry

Send now