High Temperature Permanent SmCo Magnet SmCo5 Sm2co17

High Temperature Permanent SmCo Magnet Permanent Samarium Cobalt magnets (SmCo) are composed of samarium, cobalt and iro;

Basic Info

| Model NO. | Sm2Co17, SmCo5 |

| Certification | RoHS, CE, ISO |

| Composite | SmCo |

| Type | Permanent |

| Application | Motor Magnet |

| Shape | According to Clients′ Requests |

| Coating | No |

| Density | 8.3-8.4 g/cm3 |

| Composition | Rare Earth Magnet |

| Transport Package | Standard Air and Sea Package |

| Specification | Arc, ring, block and disc |

| Origin | Ningbo |

| HS Code | 8505111000 |

| Production Capacity | 1000000 Pieces Per Month |

Product Description

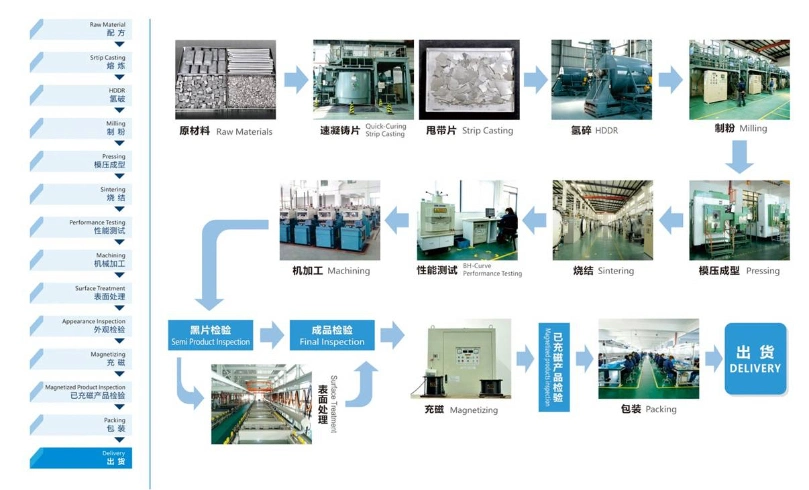

High Temperature Permanent SmCo MagnetPermanent Samarium Cobalt magnets (SmCo) are composed of samarium, cobalt and iron. These rare earth magnets are extremely strong for their small size, metallic in appearance and found in simple shapes such as Arc, rings, blocks and discs.

Attributes of Samarium Cobalt:

1. High resistance to demagnetization

2. High energy (magnetic strength is strong for its size)

3. Good temperature stability

Applications of Samarium Cobalt:

Computer disc drives, sensors, traveling wave tubes, linear actuators, satellite systems, motors where temporary stability is vital.

| Technical data of SmCo Magnet | |||||||||||||

| Material | Grade | Energy Product(BH)max | Residual Induction Br(min-max) | Coercive Force Hcb(min-max) | Intrinsic Coercive Force Hcj(min-max) | Density D | Rev. Tenp Coeff α(Br) | Curie Temp TC | Max Working Temp Tw | ||||

| KJ/m 3 | MGsOe | T | KGs | KA/m | KOe | KA/m | KOe | g/cm 3 | %/ºC | ºC | ºC | ||

| SmCo5 | XG16 | 120~143 | 15~18 | 0.77-0.86 | 7.7-8.6 | 613-716 | 7.7-9.0 | ≥1194 | ≥15.0 | 8.3 | -0.04 | ≥740 | 250 |

| XG16H | 120~143 | 15~18 | 0.77-0.86 | 7.7-8.6 | 613-716 | 7.7-9.0 | ≥1592 | ≥20.0 | |||||

| XG18 | 135~159 | 17~20 | 0.81~0.92 | 8.1~9.2 | 637~756 | 8.0~9.5 | ≥1194 | ≥15.0 | |||||

| XG18H | 135~159 | 17~20 | 0.81~0.92 | 8.1~9.2 | 637~756 | 8.0~9.5 | ≥1592 | ≥20.0 | |||||

| XG20 | 151~175 | 19~22 | 0.85~0.95 | 8.5~9.5 | 637~756 | 8.0~9.5 | ≥1194 | ≥15.0 | |||||

| XG20H | 151~175 | 19~22 | 0.85~0.95 | 8.5~9.5 | 637~756 | 8.0~9.5 | ≥1592 | ≥20.0 | |||||

| XG22 | 167~191 | 21~24 | 0.89~1.0 | 8.9~10.0 | 661~772 | 8.3~9.7 | ≥1194 | ≥15.0 | |||||

| XG22H | 167~191 | 21~24 | 0.89~1.0 | 8.9~10.0 | 661~772 | 8.3~9.7 | ≥1592 | ≥20.0 | |||||

| Sm2Co17 | XGS24M | 175~199 | 22~25 | 0.92~1.04 | 9.2~10.4 | 318~788 | 4.0~9.9 | 398~1194 | 5.0~15.0 | 8.4 | -0.03 | ≥850 | 350 |

| XGS24 | 175~199 | 22~25 | 0.92~1.04 | 9.2~10.4 | 661~796 | 8.3~10.0 | 1194~1990 | 15.0~25.0 | |||||

| XGS24H | 175~199 | 22~25 | 0.92~1.04 | 9.2~10.4 | 661~804 | 8.3~10.1 | > 1990 | > 25.0 | |||||

| XGS26M | 191~215 | 24~27 | 1.0~1.06 | 10.0~10.6 | 318~796 | 4.0~10.0 | 398~1194 | 5.0~15.0 | |||||

| XGS26 | 191~215 | 24~27 | 1.0~1.06 | 10.0~10.6 | 677~820 | 8.5~10.3 | 1194~1990 | 15.0~25.0 | |||||

| XGS26H | 191~215 | 24~27 | 1.0~1.06 | 10.0~10.6 | 677~820 | 8.5~10.3 | > 1990 | > 25.0 | |||||

| XGS28M | 207~231 | 26~29 | 1.04~1.10 | 10.4~11.0 | 318~804 | 4.0~10.1 | 398~1194 | 5.0~15.0 | |||||

| XGS28 | 207~231 | 26~29 | 1.04~1.10 | 10.4~11.0 | 677~820 | 8.5~10.3 | 1194~1990 | 15.0~25.0 | |||||

| XGS28H | 207~231 | 26~29 | 1.04~1.10 | 10.4~11.0 | 677~820 | 8.5~10.3 | > 1990 | > 25.0 | |||||

| XGS30M | 223~247 | 28~31 | 1.07~1.12 | 10.7~11.2 | 318~804 | 4.0~10.1 | 398~1194 | 5.0~15.0 | |||||

| XGS30 | 223~247 | 28~31 | 1.07~1.12 | 10.7~11.2 | 700~828 | 8.8~10.4 | 1194~1990 | 15.0~25.0 | |||||

| XGS30H | 223~247 | 28~31 | 1.07~1.12 | 10.7~11.2 | 700~828 | 8.8~10.4 | > 1990 | > 25.0 | |||||

| XGS32M | 231~255 | 29~32 | 1.09~1.15 | 10.9~11.5 | 318~804 | 4.0~10.1 | 398~955 | 5.0~12.0 | |||||

| XGS32 | 231~255 | 29~32 | 1.09~1.15 | 10.9~11.5 | 716~836 | 9.0~10.5 | > 955 | > 12.0 | |||||

| Low Temp Coeff Sm2Co17 | XGS22LT | 159~183 | 20~23 | 0.90~0.99 | 9.0~9.9 | 677~756 | 8.5~9.5 | ≥1194 | ≥15.0 | 8.4 | -0.015 | ≥850 | 350 |

| XGS24LT | 175~199 | 22~25 | 0.92~1.02 | 9.2~10.2 | 677~756 | 8.5~9.5 | ≥1194 | ≥15.0 | |||||

You may also like

Send inquiry

Send now